Optimize jerk in motion profiles for high performance applications

Used In:

- General operations, to maximize performance

- Low-rigid mechanics operations, to reduce vibration

- Friction-based transmission mechanics, to reduce slippage

Used In:

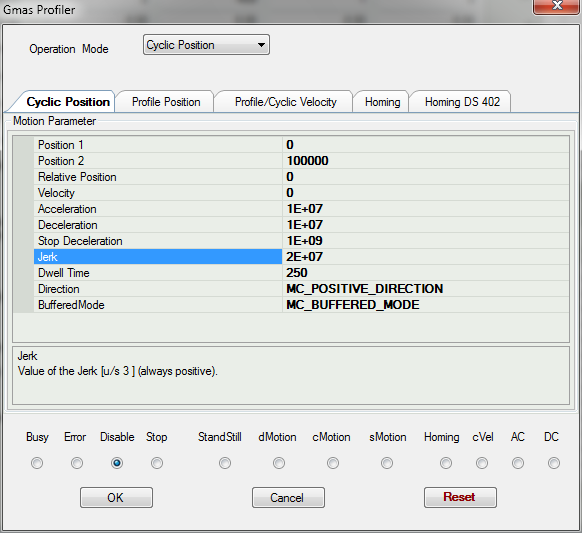

Unlike most servo controllers available on the market, the Gold Maestro (G-MAS) provides real time, high precision calculation and control over jerk during a motion sequence.

Jerk is defined as the rate of change in acceleration, a derivate of acceleration with respect to time. By adjusting jerk parameters, it is possible to ramp the acceleration rate and smooth the motion velocity profile, thus preventing excess mechanical system oscillation. Reducing oscillations makes it possible to maximize the acceleration parameters of an application and so significantly improve machine performance.

Jerk control is powerful feature of the G-MAS profiler. Using this tool, a user can optimize a motion sequence to obtain optimum performance.

G-MAS jerk control is especially beneficial for machines used in the semiconductor industry and similar advanced equipment. It can prevent vibration in low-rigid mechanics and can prevent slipping of mechanical parts in friction-based mechanics, like vehicle transmissions or certain kinds of elevation equipment.