Connect motion segments with smooth kinematics and geometric shapes

Used In:

- Motion sequence simulation and testing

- Any ECAM application using multiple slave axes in addition to the main axis

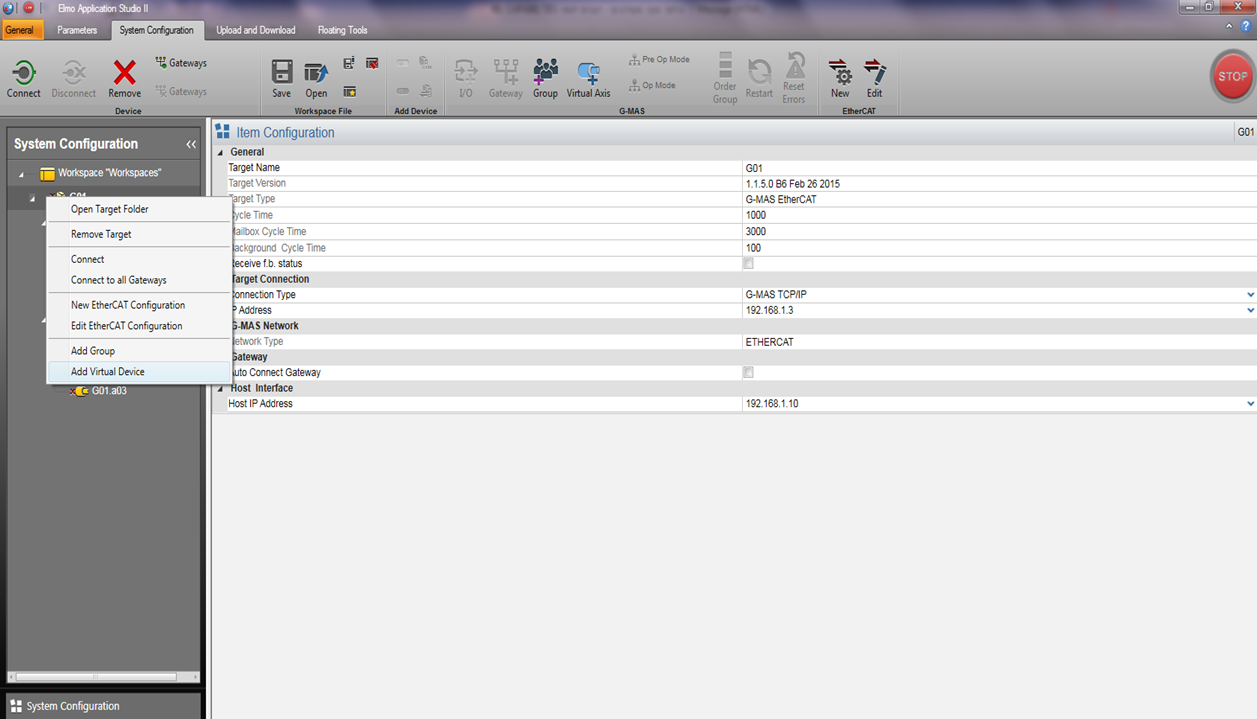

The G-MAS can create and operate ‘virtual’ axes, enabling computed simulation of machine motion sequences for prototyping applications.

Because a virtual axis does not physically exist, during operation its driver will not produce demand output or require any physical feedback. All position and velocity data for a virtual axis is generated internally and is functionally identical to the demand values produced by the motion profiler.

The advantages of using virtual axes include: