Background

Advanced cardiac imaging systems employ nuclear imaging techniques and other innovative technologies to enable high throughput and enhanced image resolution. One manufacturer designed a machine that can complete a Gated SPECT study in just two minutes, a significant improvement over older technologies that required 12-20 minutes. This breakthrough in speed and image quality is due to features such as:

- Larger radiation collection angles and a unique scan pattern provide photon collection that is X10 more efficient, leading to improved count statistics and higher quality images.

- Novel design of solid state scanning detectors and unique reconstruction algorithms that improve resolution by a factor of >2.

- Automation and personalization of image acquisition.

Read this case study to learn how:

- Small-sized servo drives allowed the customized design of PCB which was tailored to meet the specific needs of the customer.

- Low EMI emission of Elmo’s servo drives enabled the product to comply with strict standards of the medical industry.

- Advanced software of Platinum Maestro shortens time to market.

Machine Requirements

The company designed a new, sophisticated cardiac image scanning machine that included nine collimators placed on rotary axes that could scan the target angularly. A tenth axis moved the base of the nine collimators angularly to align them with the target body. All scanning motion was internal and invisible to the patient.

The company needed a compact motion solution with minimal wiring that would enable mechanical integration in the tight machine space. Furthermore, it needed to include a fast serial communication channel that could move and stabilize the heads at the next image capturing point in a window of just 40 msec from the time that the computer issued the command.

Due to the medical environment and EMI issues, the solution also had to be compliant with the relevant EMI standards.

Motion Control Solution

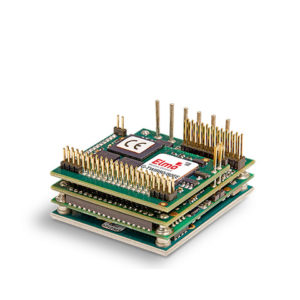

- Gold Twitter servo drives

- Platinum Maestro motion controller

Elmo’s Gold Twitter digital drive was chosen for this application, due to its compact size and ability to integrate within the constraints of the machine’s interface. The Gold Twitter, like all Elmo drives, is compliant with medical EMI standards, eliminating the need for an external filter.

10 G-TWIs were chosen to move the collimators’ angular axes and the collimators’ base angular motion. Elmo’s Platinum Maestro controller was used to control the motion of all axes, communicating with the ten Gold Twitter drives via CANopen communication. The cardiac imaging system’s PC issues commands to the Maestro using TCP/IP communication. With Maestro, the scanner’s on-board processor no longer needs to handle the CANopen communication or the motion control processes.

Elmo can either design custom PCB interface boards or support its customer’s teams in designing their own boards. In this case, the Elmo team assisted the company’s team in designing the Gold Twitter’s interface board to match the machine’s mechanical constraints. The interface board was then tested and approved by Elmo’s engineers.

Gold Twitter

Servo drive, Up to 80A/80V, 70A/100V, 30A/200V

Platinum Maestro

High Precision Ethercat Muilti-Axis Motion Controller

Results

Elmo’s high-performance servo drives allowed the cardiac imaging system to meet the high demands of the motion profile. The distributed communication required minimal cabling, saving both space and costs. Elmo’s Platinum Maestro controller was integrated quickly with the machine motion, and together with its advanced software, shortened the time to market. Throughout the process, Elmo provided comprehensive support to the medical engineers who designed and built the cardiac imaging system.

For More Information