Description

High Power Super Compact, Direct to Mains, Network-Based Servo Drive (Up to 65 kW)

The Gold Drum HV 100 A/800 V is the highest power Gold Servo Drive. Designed to operate “Direct to Mains” from a rectified 480 VAC (+10%).

The Gold DRUM HV meets the highest level of motion control application requirements, providing top servo performance, advanced networking, built-in safety and high power density, combined with a fully featured motion controller and local intelligence.

In conjunction with Elmo’s Gold Maestro, the ultimate distributed network motion controller, and the other members of Elmo’s Gold Line of intelligent servo drives, state-of-the-art solutions for the most challenging multi-axis motion applications can be easily implemented, with a short development cycle.

Read our application note on Thermal Management to discover how to achieve efficient, cost-saving heat dissipation while using the Gold Drum HV.

Gold Drum HV Highlights:

- Gold Line core motion control technology

- Ultra-compact, highest power density

- Highly efficient ≈99%

- High servo performance, wide current, velocity, position bandwidth

- Real-time deterministic network communications: EtherCAT, CANopen

- Host communication: USB, Ethernet

- Supports a wide variety of feedback sensors in single, dual and gantry loop configurations

- Advanced tuning, filtering and gain scheduling options for enhanced dynamic performance

- Vector control sinusoidal commutation

- Easy to set up and tune with Elmo Application Studio software tools

- Windows-based application enables users to quickly and simply configure the servo drive for optimal use with their motor

- Complies to safety and EMC STD: IEC61800, UL508c, UL60950, EC61800-5-2

- EtherCAT slave drives with rotary switches allow the user to define a unique node ID to a slave

- The two rotary switches offer up to 255 addresses, with the 0 setting referring to No alias address

400 V Type

Feature | Units | 50/400 | R100/400 |

|---|---|---|---|

Minimum supply voltage | VDC | *For H, S, T, or A option = 50 | |

Nominal supply voltage | VDC | 325 | |

Maximum supply voltage | VDC | 400 | |

Maximum continuous power output | kW | 16.5 | 33 |

Efficiency at rated power (at nominal conditions) | % | > 98 | |

Auxiliary supply voltage option | VDC | 18 to 30 VDC (only in H, S, T, or A option) | |

Auxiliary power supply | VA | ≤5 VA without external loading | |

Continuous current limit (Ic) Amplitude | A | 50 | 100 |

Continuous RMS sinusoidal commutation current limit (Ic) | A | 35 | 71 |

Peak Current | A | 100 | No Peak |

Mounting method |

| Panel / Wall Mounted | |

800 V Type

Feature | Units | 35/800 | 50/800 | R70/800 | R100/800 |

|---|---|---|---|---|---|

Minimum supply voltage | VDC | *For S, T, or H option = 95 | |||

Nominal supply voltage | VDC | 560 for 400 VAC | |||

Maximum supply voltage | VDC | 780 | |||

Maximum continuous power output | kW | 22.5 | 32.5 | 45 | 65 |

Efficiency at rated power (at nominal conditions) | % | > 98 | |||

Auxiliary supply voltage option | VDC | 18 to 30 VDC (only in S, T, or H option) | |||

Auxiliary power supply | VA | ≤5 VA without external loading | |||

Continuous current limit (Ic) Amplitude | A | 35 | 50 | 70 | 100 |

Continuous RMS sinusoidal | A | 25 | 35 | 50 | 71 |

Peak Current | A | 70 | 100 | No Peak | No Peak |

Mounting method |

| Panel / Wall Mounted | |||

Feature | Units | All Types |

|---|---|---|

Weight | g (oz) | 1.65 Kg (58.202 oz) |

Dimension | mm (in) | 180 x 142 x 75.2 (7.08" x 5.53" x 2.96") |

Mounting method | Panel / Wall Mounted |

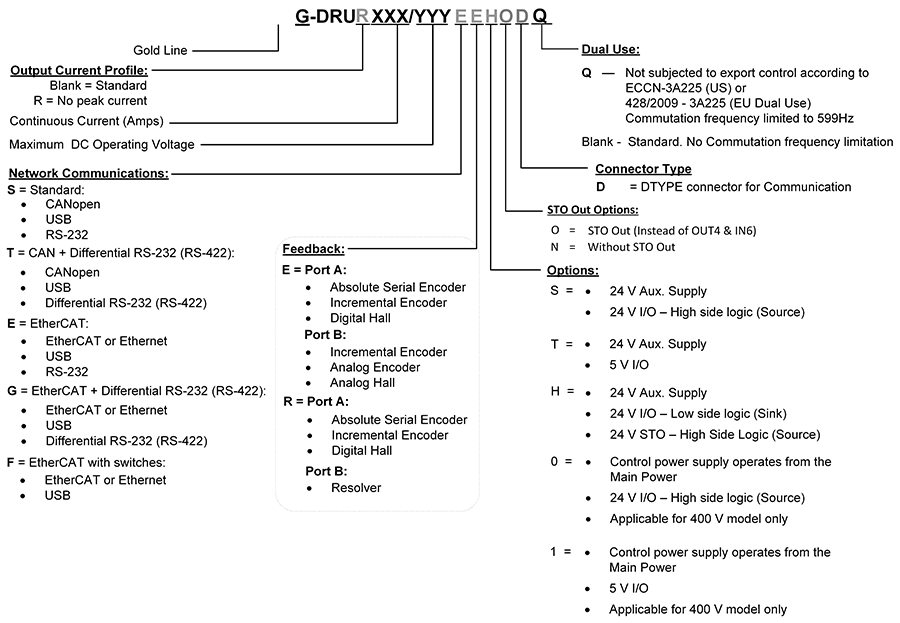

D Type connectors

RJ 45 connectors