Today’s passenger expects a consistent, high-speed internet connection at all times, even when in the air. The quality and availability of that connection can be a deciding factor when choosing an airline. But how does in-flight Wi-Fi actually work? Some of the technology behind the miracle of airplane Wi-Fi actually resembles the process that delivers wireless internet on the ground. Airplanes use many of the same towers and satellites that deliver data to our smartphones, by connecting to towers on the ground as well as satellites. However when it comes to airplanes the information is transmitted to and from your smartphone via an antenna on top of the aircraft. Since airplanes move through the stratosphere at such high speeds, the antenna must constantly maintain a connection to any given tower or satellite. In order to maintain this connection Two ExtrIQ Gold Bees are installed inside each antenna to control the azimuth and the elevation. This 2 axis motion allows the antenna to constantly face a tower on the ground or a satellite in space and by that have a continued connection to Wi-Fi. This kind of motion requires high precision so the antenna can perfectly align itself with satellites or ground towers. Given the location of the antenna, it can be subject to vibrations and shocks. As the airplane reaches high altitudes the temperatures are extremely low and can even reach -55°C. For this reason, the ExtrIQ line was selected since it is designed to withstand extreme temperatures and shocks.

Elmo’s ExtrIQ servo drives and motion controllers are designed for missions requiring both extreme performance and harsh environment durability. ExtrIQ is the result of combining Elmo’s world class servo performance, high efficiency, and ultra-small size and weight, together with the ability to withstand extreme environmental conditions. Field proven for over 15 years, ExtrIQ products are driving applications day and night on the ground, in the air, and underwater. They can withstand mechanical shocks of up to 75G, vibrations of 20Hz-2000Hz (14.6 Grms) and a temperature range of -40°C to 70°C.

For this specific case Elmo provided a version of the drive that can reach an operating temperature of -55°C following the costumer’s demand.

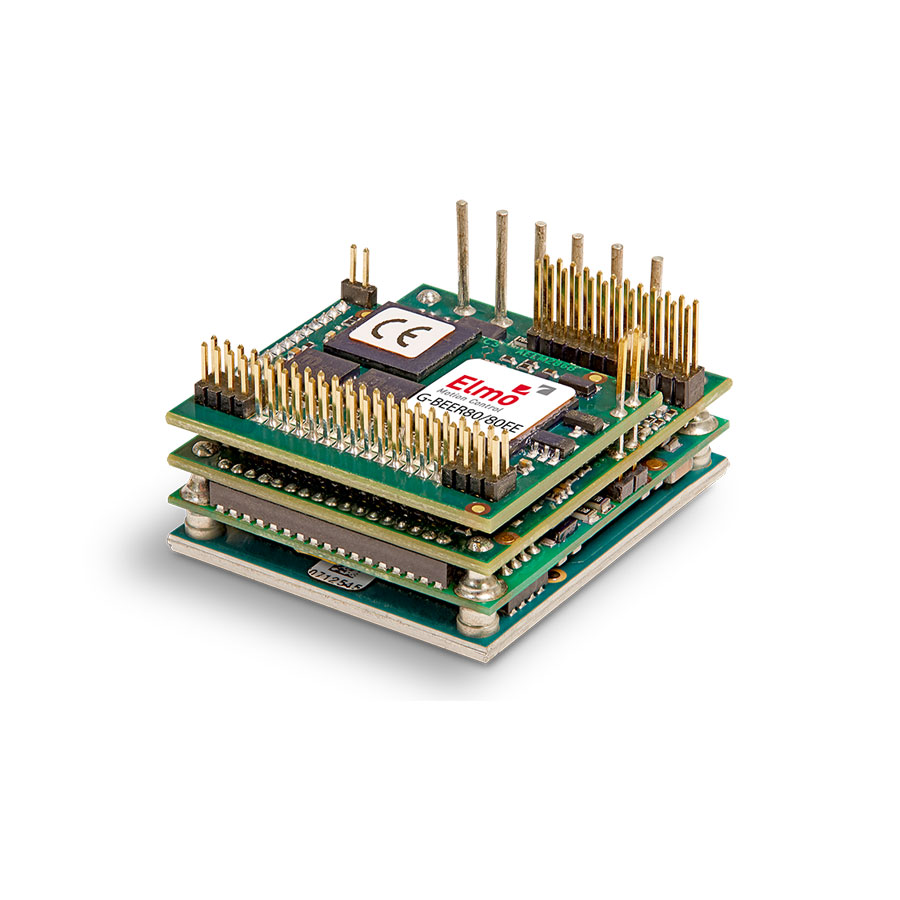

The Gold Bee’s miniature pin based version of only 30 mm/35 mm, made it easier for the drives to be incorporated on the application’s own PCB.