Support for delta robot kinematics using multiple coordinate systems

Used In:

- Multi-axis applications requiring accuracy and speed in a small workspace

Used In:

Delta robots are used in many areas of industry today. The common requirements of these applications include:

Delta robot kinematics are simple. After defining the basic mechanical characteristics of the robot, it is possible to make use of many pre-defined motion sequences and interfaces. The same motion sequence can be run in different robots with different mechanical properties.

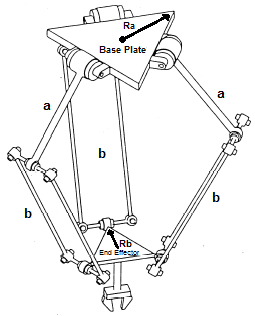

The delta robot definition process requires mechanical specification of:

During operation, a limit handling mechanism can be used to protect the system, including axis limits and machine limits.

The G-MAS also supports a special Cartesian transformation function from Machine Coordinate Systems (MCS) Product Coordinate Systems (PCS).

See G-MAS Coordinate Systems and Kinematics for more information on how G-MAS controls multi-axis kinematic systems.

Presentation: The Kinematic System in G-MAS