Background

Automatic dispensing machines have become an integral part of the manufacturing processes of many industries, from Electronics Assembly and Packaging to Medical and Pharmaceutical. You can apply paints, coatings, and adhesives with high precision and throughput thanks to robotic dispensing. When the world’s leading precision fluid dispensing systems manufacturer needed to introduce a new automated dispensing gantry robot, Elmo’s motion control solution helped achieve the desired end.

Read this case study to learn how:

- Powerful high-density Gold servo drives control the Gantry robot.

- Polynomial corner blending is used to limit jerk and acceleration.

- The Platinum Maestro distributed network controller provides means of synchronizing motion of the dispense system via I/Os.

- Single head or dual head configurations of the Gantry system support different motion modes.

Machine’s Requirements

A new dispensing robot had to provide the speed, accuracy and flexibility for precise and demanding applications. A new dispensing machine was Gantry-based and included Y, X, Z and Delta Y axes.

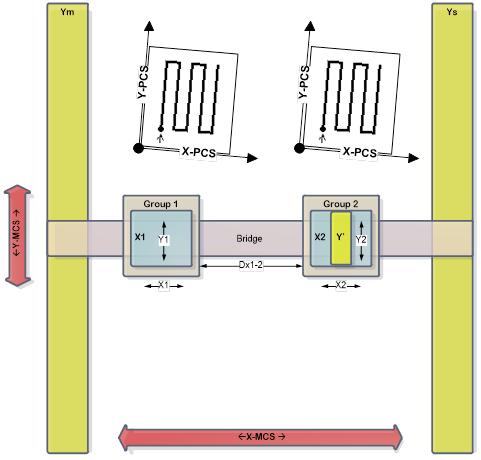

The new machine had to support different types of motions along pre-defined shapes, in different orientations. To do so, the coordinates system of the gantry robot had to undergo a special transformation.

The provider of the motion control solution had to ensure effective servo performance and tuning tools, enabling control of the Gantry system. The system had to achieve dispense speeds of 30, 50, and 100mm/s, static accuracy of 5 µm, dynamic accuracy along the dispense path of 25 µm, and velocity of 1.5m/s to 2m/s. The acceleration rate had to be 1.5g, jerk: 500m/s^3.

The Elmo Motion Control Solution

- Gold Whistle servo drives

- Gold Trombone servo drives

- Platinum Maestro Controller

- Tambourine Power Supply

The resulting system is a gantry based dispensing robot with 4-7 axes of motion. The axes are controlled by Gold servo drives.

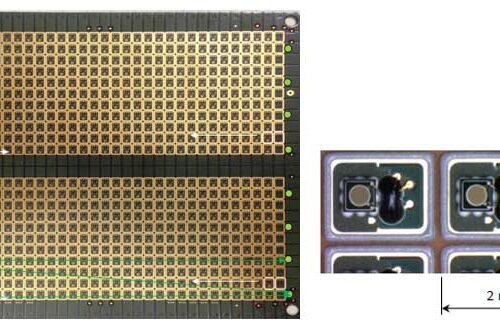

The drives are mounted onto a custom PCB (backplane) which is designed to allow for optional configurations; these are plug-in drives, as required by the mechanical configuration. Gold Trombone drives are used for the X & Y linear motor axes, while Gold Whistle drives are used for the Z and delta Y axes.

In addition, Tambourine Power Supply is used to power the Gold Trombones used to drive the X & Y axes.

To enable different motion modes, as required by the customer, a number of configurations are offered by Elmo:

- Single Head system is the base configuration and is an XYZ Gantry system. In this case, the machine includes only one head, and performs the pre-defined motion along the shape, one shape at a time.

- Dual Head systems include additional linear motor forcer on the X axis, additional Z axis stage mounted on the 2nd X forcer, and optional Delta-Y wedge stage mounted on the Z axis. In this case, the machine includes two heads. Head 1 and head 2 have shift in X/Z direction, and perform the pre-defined motion along the shape, one shape at a time. Alternatively, the motion can be performed along 2 shapes simultaneously. The shapes are shifted only in X/Y/Z offset, but have the same orientation (rotation angle). As a further possibility, shapes can be in different orientations, both in X/Y/Z offsets, and given rotation angle.

Dual Head/Shape Motion, Same Orientations (X/Y/Z Shift Only)

Processed parts

The Outcome

Integrating Elmo’s best-in-class pin based high performance servo drives, smart controller, and power supply in the dispensing machine provided a complete solution for the customer. While the Platinum Maestro controls all motion, interfacing with the customer’s system/user software through a dedicated .NET DLL, Elmo’s small yet powerful drives incorporate just the right algorithms to satisfy the need for speed, precision, accuracy and performance of the dispensing robot. Different single head / dual head configurations of the system provided the flexibility required by the customer.

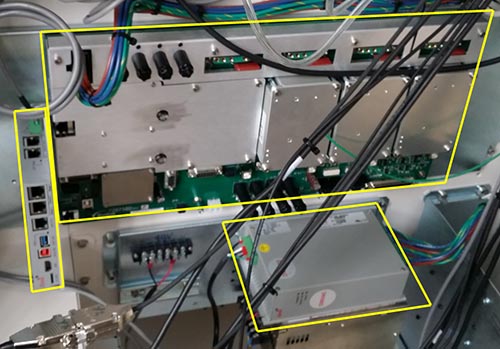

Backplane, PMAS, and TAM are highlighted in the picture. This is from a single head system where (3) G-TRO and (1) G-WHI are used.

Gold Trombone

Compact High Voltage Servo Drive

6-22A/400VDC, 8-16A/800VDC,

*900VDC optional

Gold Whistle

Miniature Servo Drive

1-20A/100VDC, 3-9A/200VDC

Platinum Maestro

High Precision Ethercat Muilti-Axis Motion Controller

Tambourine-20

The Tambourine (TAM-20) is Elmo’s compact, direct-to-mains power supply, designed for multiple servo drives.

For More Information