The Perfect Motion For Any Robot.

A 7-Joint Arm Robot Performing ‘T’ai Chi Ch’uan’

Elmo’s Ultimate Multi-Axis and servo solution incorporated in the design and development of the first Chinese Collaborative Robot by Siasun, China

Elmo’s ultimate Motion Control solution is boosting the new design and answering the challenges of the first manufacturing floor Collaborative Robot Coworker developed by Siasun, a leading Chinese robotic company. Imagine a robot that perfectly emulates the motions of a martial arts ‘T’ai Chi’ Master – with precision, accuracy, speed, and power.

Consider the important meaning of an integrated robot collaborating with humans in the real-world manufacturing floor, complying with critical and mandatory safety constraints. Using Elmo’s unique and advanced servo technology, one of China’s leading companies in the field of robotics and automation has just completed the development of its first homegrown human-machine collaborative factory-automation robot. Elmo provided ultra-small and powerful network based servo drives, which were mounted directly onto the robot joints.

This proved to be advantageous for numerous reasons among which were efficiency, ruggedness, space saving, minimum cabling, low EMI, and overall increased reliability of the system. Achieving maximum servo performance with dual servo loops, and operating high resolution absolute encoders were just some of the challenges confronted when building this sophisticated, collaborative 7-joint arm robot in record time. Elmo’s proven record in the field of high end motion-control robotics was instrumental in reaching the highest levels of multi-axis and servo performance during the development process.

Abstract

Collaborative robots designed to work in close proximity with people are becoming a commonplace in the factory production floor. These robots are perfectly adapted for precise, high speed and high accuracy tasks, in human –robot environments. Using cameras, force sensors, and other sensing elements, these robots sense human presence and respond accordingly, sometimes completely stopping, to avoid human injury. These robots are usually designed to handle small parts with high dexterity, and assist with such tasks as assembling consumer-electronics items, rather than performing heavy duty tasks such as lifting heavy materials, welding or painting. The typical collaborative robot construction is relatively small and lightweight, however still has the ability to lift relatively heavy payloads of up to 100 kg.

Along with the high performance dexterity, ,the robot must also have the ability to sense whether parts are assembled correctly and constructed precisely, an unimaginable feature in previous generations of heavy industrial robots. Older factory 6-joint traditional robots typically move their heavy arms with considerable force, causing serious injury to any approaching human.

The new generation of robots has an added joint, or degree of freedom. Compared to traditional 6-Degrees of Freedom (6-DOF) robot, the 7-joint (7-DOF) robot allows the arm to extend for a specific part in multiple orientations, therefore avoiding collisions with a human, yet continuing its task. Additionally, the kinematic redundancy is very useful for operating several robots within a confined space, since preventing obstructions is easily managed.

An added feature of these robots is the force sensing, control and limiting. The robot senses and responds to the slightest external force enabling collision prevention. In some cases, force sensors located after the motor gear box are used to detect any rapid increase in the external force, while in other cases, the robot identifies the required amount of force to raise a load and move it from one position to another. When it recognizes a required increase in torque for movement, such as in a collision, the robot stops. Another feature for collision detection and avoidance is the ability to change the control mode from the inflexible, full-speed mode (such as CSP – cyclic synchronous position or CSV- cyclic synchronous velocity), to a torque mode (CST- cyclic synchronous torque) when unexpected contact with an object or human is detected. The soft, compliant CST mode allows the robot to be easily pushed away by a human hand. The robot can be armed to enter the compliant mode automatically as it detects contact, or disarmed to run in inflexible mode at full speed.

Another important mode is the Teach Mode, during which the operator moves the robot to desired locations, while the Elmo controller records these positions for future trajectories in operational mode. Important to note is the incredible sensitivity and resolution accuracy during the teaching process. Even more amazing is the feature simplicity and the fact that most tasks can be accomplished with no previous programming experience.

Elmo Solution – The Servo Drives

Elmo’s ultra-small and powerful Ethercat Gold servo drives were selected for the challenging task. The drives were mounted directly onto the robot joints, and were a perfect choice for maintaining the small size and compactness of the robot. Two powerful ultra small Gold SOLO GUITAR drives were used to drive the two base joint motors that support the whole mechanical structure of the robot. The ability to drive the motors with continuous current of 50 Amps and high peak current of up to 100 Amp allowed reaching the required high speed, acceleration, and deceleration operation rates. Additional five miniature Gold SOLO WHISTLE drives capable of running 20 Amps continuous current, and up to 40 Amps peak current were used to operate the additional five robot joints. Each drive in the system operates at maximum speed, acceleration and deceleration rates, yet also required to operate at slow speeds with extremely high accuracy and precision. Such polar opposite operation using same drive is made possible by the exceptional 1:2000 dynamic current range, and the very wide bandwidth response of the drives.

A drive with a sufficiently small physical footprint such that it could be mounted directly onto the robot joint, was the only option for such complex project. Positioning the drives in close proximity to the servo feedback resulted in minimum cabling, minimum influences of external noise, low EMI and RFI, and overall dramatic increase in the reliability of the system. Another drive characteristic that promoted integration within the robot joints is the innate ruggedness and ability to withstand the high mechanical acceleration and deceleration rates within each of the joints.

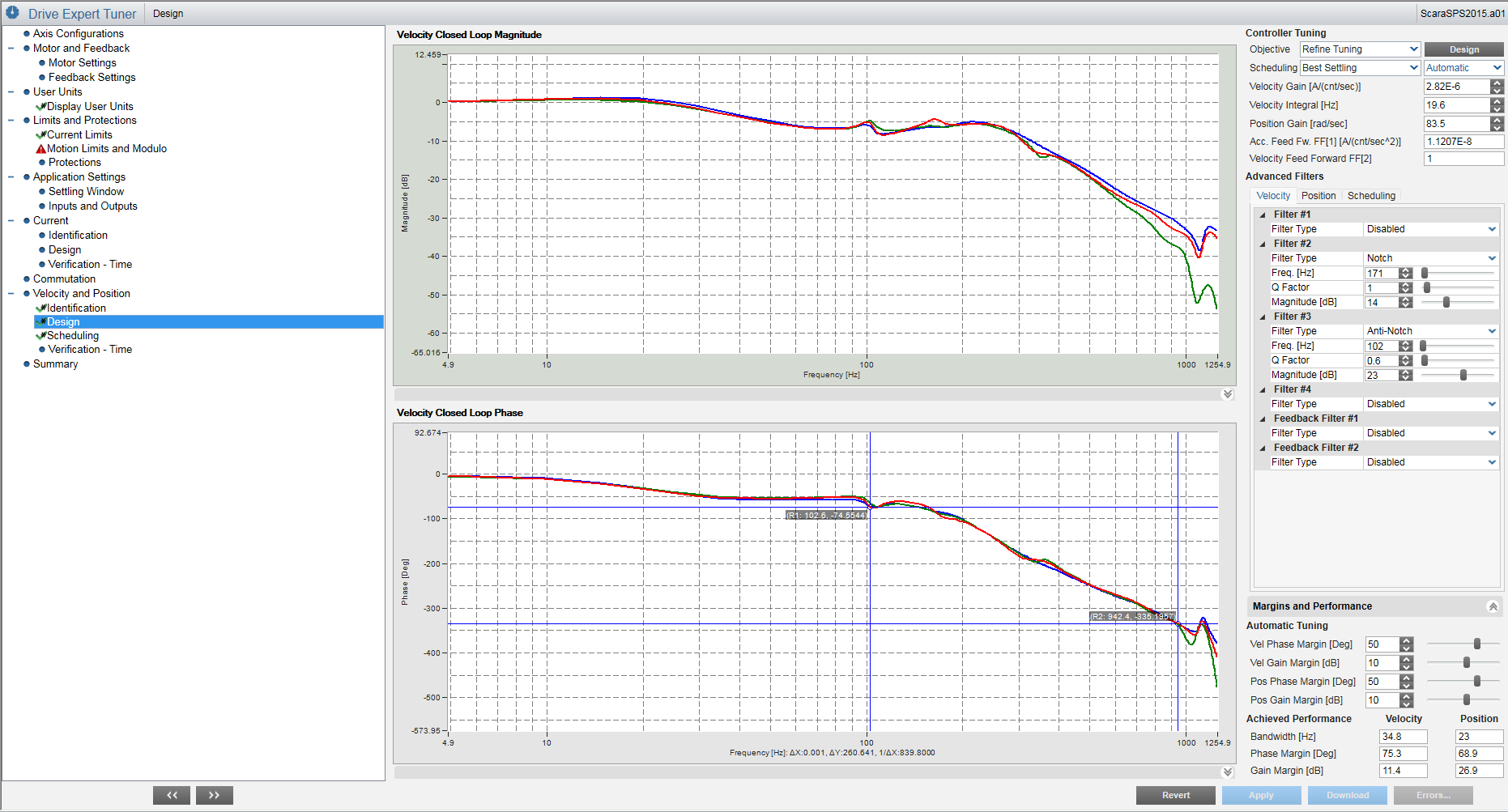

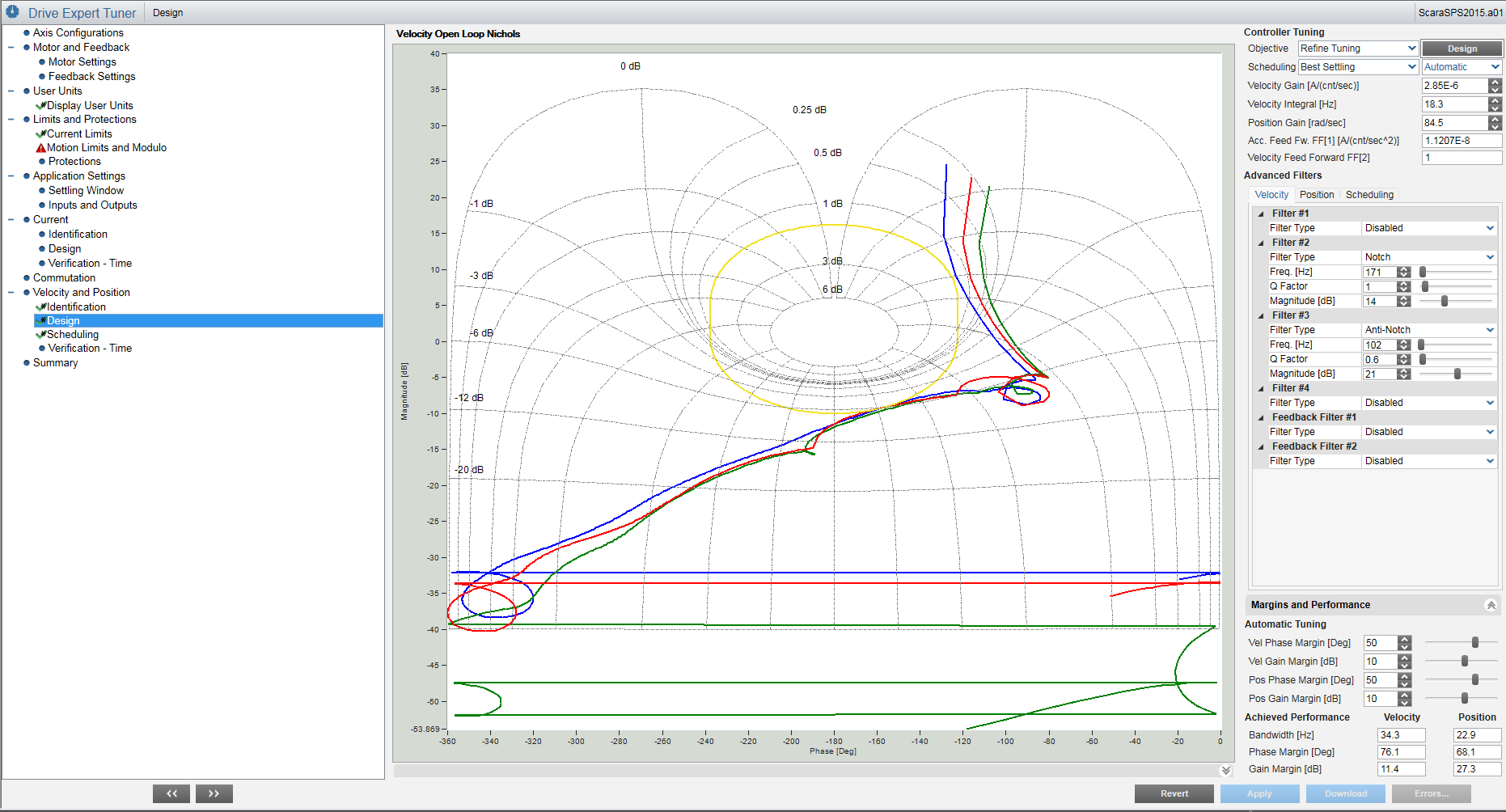

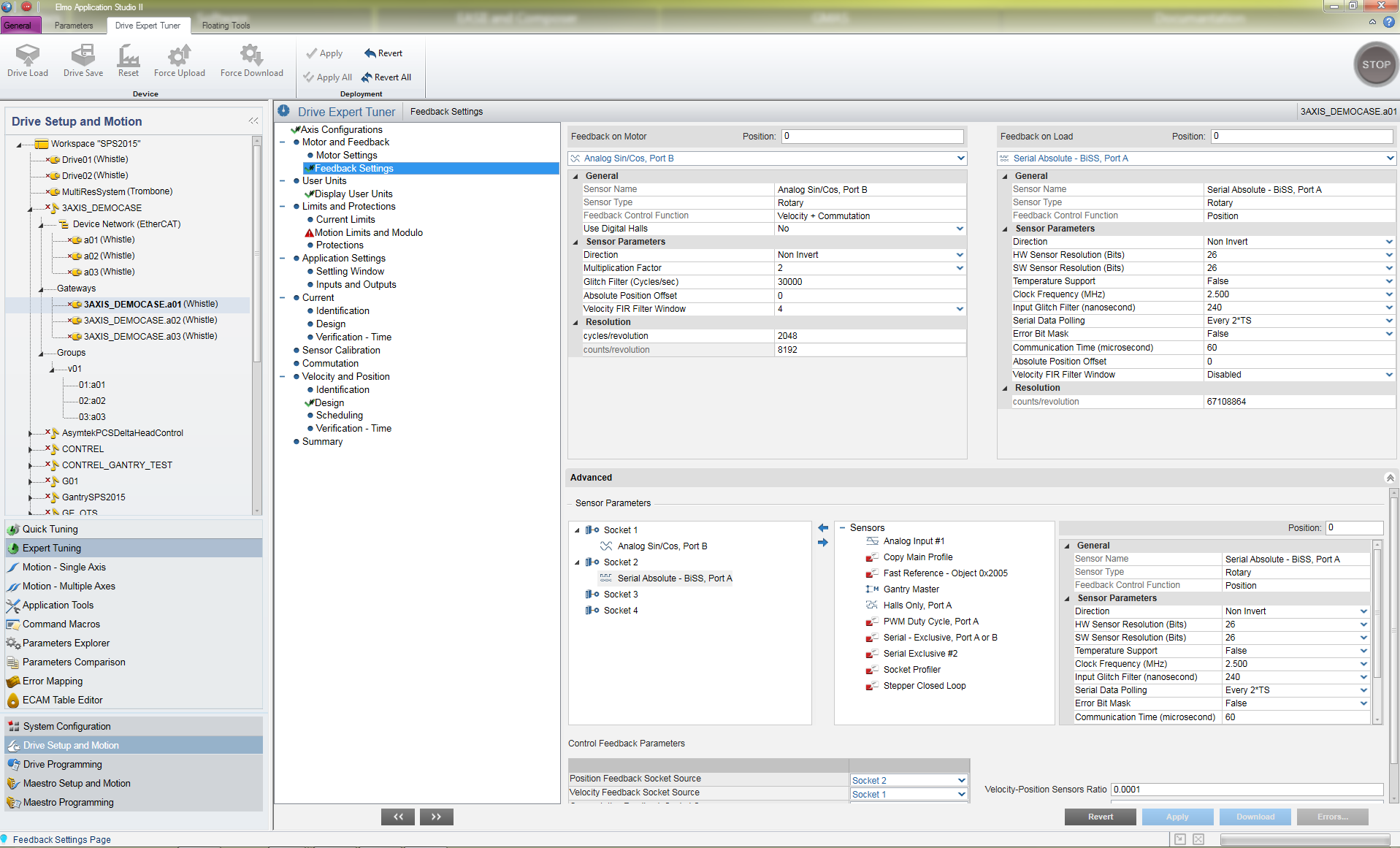

The EASII (Elmo Application Studio)

Elmo’s highly advanced yet simple to use configuration tool, the EASII, (the tool that “does it all for you”) assisted in tuning each of the individual drives in the network to their highest level for optimized servo performance. System Identification and suitable controller design, using high order filters to overcome imperfections in the mechanical structure, were just some of the tools implemented to elevate the system to its highest possible servo performance.

Further, multi axis identifications using simplified and advanced identification methods with special position gain scheduling to eliminate the crossover-effects between the various axes were implemented. Many other feature were used in this application, all for operating the system with the highest possible bandwidth, fastest response time, and simultaneously maintaining stability and smooth robot operation with high margins.

Each axis in the system operates in a dual loop servo control architecture to increase the position accuracy of the system after the gear box. Closing dual loop control with an incremental encoder together with digital hall sensors for the inner velocity control loop before the gear box, while closing the outer position control using a 19-bit high resolution absolute feedback is just one of the multi cross-feedback connection options available in all Elmo Gold drives as a standard feature. The dual loop structure boosted the local servo operation to its highest optimized performance. For simple customer connectivity each pin based drive in the system was supplied with its integrated SOLO board. The SOLO board allows simple connectivity and integration by the customer by allowing simple EtherCAT, I/O and feedback connectivity.

The Platinum Maestro, The Ultimate Multi- Axis Controller

Controlling the whole system is Elmo’s advanced multi axis controller, the Platinum Maestro (P-MAS), over real time deterministic serial EtherCAT networking with 16 axes fully synchronized at cycle time of 250us (down to 100us cycle time with 8 fully controlled axis). Elmo’s proven ability to support a wide range of built-in robot kinematics using the P-MAS, with mechanisms such as Cartesian, SCARA, 3- link, Delta etc. makes it easy to answer any robotic challenge.

The built-in kinematic support operates in either MCS (Machine Coordinate System) or PCS (Product Coordinate System) with full synchronization to turn tables, conveyors and other external equipment. In addition, the P-MAS has a special real-time code section for user applications. This special code section enables robot developers to write their own specific robot kinematic equations, enabling the P-MAS to support any high‑end, unrestricted robot types available today, where users can implement their own specific kinematics.

The P-MAS, which is based on the newest 4-Core powerful processor is essential in this kind of applications requiring real-time calculation of the robot kinematics and inverse kinematics within network cycle time of 250µSec. The kinematic equations implemented in the user input real-time section, calculate the target positions/velocities or torque of all the axes in the system and output them on each EtherCAT cycle. Operating the system in one of the DS-402 cyclic synchronous modes is a built-in standard operation of each of Elmo’s EtherCAT compliant servo drives. The wide variety of standardized and proprietary communication protocols between the P-MAS and Host computer, PLC, or HMI enables fast and simple communications with 3rd party elements such as touch panels, teach pendants, PLCs, computers, etc.

Host communication capabilities such as Ethernet, TCP/IP, and UDP Fast Binary Protocols such as Modbus and Ethernet/ IP, allow for simple fast and effective communication with almost any high level host in the system. The robot operation is divided into two main modes; the first is the operation teaching mode, and the second is the working mode. In the teaching mode, the operator physically moves the robot to key position points along the wanted path trajectory.

The multi axis controller records the relating position points in order to repeat the whole trajectory motion in the working mode. The drivers operate under cyclic synchronous torque (CST) mode of operation during this mode. In addition to the torque command, the multi axis controller outputs additional compensation current (torque) in order to overcome resistance factors, such as gravity and robot dynamics, while maintaining a smooth dragging process. One of the highlights of such complex robotic solution is the implementation simplicity of the teaching process for the non-programmer, where most tasks could be accomplished with no programming experience or skills whatsoever.

The second mode of operation is the working mode, where the multi axis controller calculates the seven target position/velocities according to kinematic model of the robot (Inverse kinematic solution of DH matrix), and if necessary, compensation of the torque based on the dynamic model is added to the total output torque. The drivers operate under cyclic synchronous position (CSP) or cyclic synchronous velocity (CSV) mode of operation, receiving target position/velocity commands and torque offset commands.

Solution highlights

- Unbeatable servo performance.

- 250 us cycle time for up to 16 axis fully coordinated and synchronized

- Small size servo drives with very high power rating mounted right on robot joints

- High dynamic current range for high speeds and high precision

- Dual loop control capability

- Ability to communication with variety of feedback devices (incremental and absolute encoders)

- Using powerful Multi Axis Controller for synchronization and robot motion implementation

- Fast EtherCAT real time serial deterministic networking

- Optimized servo performance -very fast response time as a result of extremely wide control loop Bandwidths

- Powerful EASII enables easy robot configuration and implementation

- Top efficiency, utmost reliability

- Ultra rugged, the drives can be mounted anywhere.

- Low EMI , RFI

Summary

Elmo’s Smart, Small, and Simple servo and motion solutions boost the performance and enhance the functionality of Siasun’s newest technology – the collaborative robot

For More Information