Turret test handler machines are designed for testing the integrity and functionality of semiconductor components. A pioneer company, specializing in design and manufacturing of industrial automation solutions, with particular emphasis and expertise in back-end semiconductor test handlers, sought a motion control solution that would fit into an intricate machine design, minimize the number of machine’s components and cables, while at the same time maximizing its performance. Elmo was able to offer a complete off-the-shelf package solution that answered all the developer’s needs.

Read this case study to learn how:

- How end-to-end partnership with Elmo helps design an innovative machine with minimal space claim.

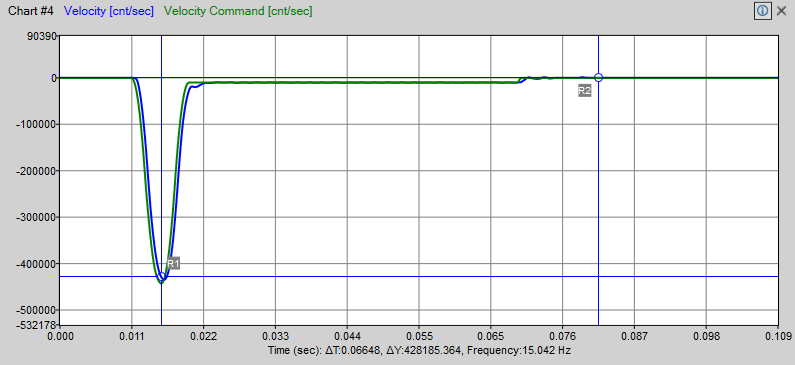

- How Elmo’s technology handles the machine’s high & low accelerations.

- High-density servo drives enabling adaptation of axis velocity on the fly.

The Machine’s Requirements

The turret machine needed to perform tests identifying physical defects and determining the electrical integrity of the internal circuit of the semiconductor components. There was a total of 10 voice coils motors that needed to be controlled and powered, all the while maintaining high machine throughput. The drives had to handle the machine’s high & low accelerations. The axis velocity needed to be adapted on the fly. In addition, the developer had strict position-to-force requirements.

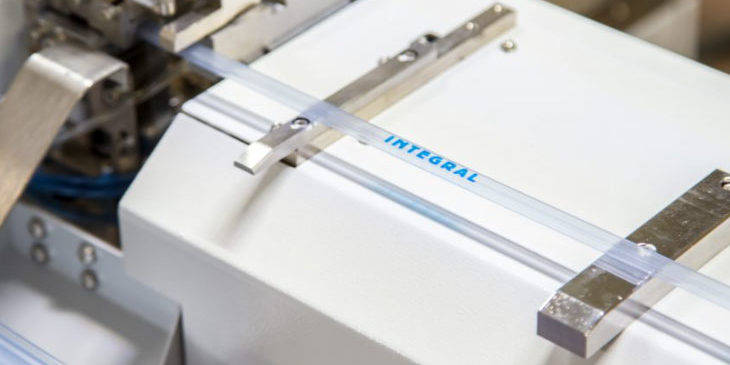

Traditional design required to wire the cables from the motors all the way down to the cabinet. In their standard design, it generally required a 5 meters-long cable to complete the connection. To enhance assembly efficiency and overall machine compactness, the company wanted to minimize electrical hardware in the design, and to eliminate cables. The equipment from Elmo needed to be limited in terms of size, but vast in terms of capabilities.

The Elmo motion control solution included:

The company chose Elmo’s Platinum Solo Bell servo drives to power its 10 motors. Platinum Solo Bell is a compact, digital servo drive and is part of Elmo’s innovative Platinum series. The drive is designed to drive any motor and has multi-axis capabilities, so 5 Platinum Solo Bells were able to control 10 voice coil motors. Mounted directly on the axes, they reduced the need for cables.

Next, for the main turret motor, Gold DC Trombone was selected to drive the high-speed rotary axis. Lastly, Gold Solo Mandolin and Gold Solo Twitter were selected to handle the rest of the applications in the system, which are mainly using small size AC rotary servomotors.

In addition, Tambourine Power Supply is used to power the main turret motor, and those AC rotary servomotors in the system. This power supply was designed by Elmo to power multiple servo drives, with direct-to-mains operation and high regenerative capabilities.

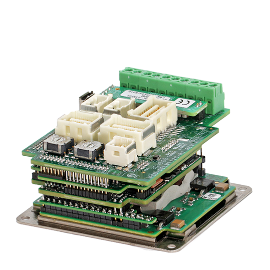

The drives meet the highest level of motion control application requirements, providing top servo performance, advanced networking, built-in safety and high power density, combined with a fully featured motion controller and local intelligence. All drives are chained with an EtherCAT network to Elmo’s Platinum Maestro master controller which manages the entire motion system.

The controller’s distributed topology enables an intelligent and modular design in which a motion control network comprised of nodes, each consisting of a servo drive with a unique EtherCAT identity, can be closely controlled and monitored by the controller. This enables seamless integration of the appropriate servo drive for each axis, providing highly accurate and responsive motion control. With Platinum Maestro at the helm, servo drives can control and monitor each and every motion. The overall motion system is extremely efficient while retaining a compact design.

The Outcome

Integrating Elmo’s best-in-class high performance servo drives, smart controller, and power supply in the turret test handler machine provided a complete solution for the customer. While the Platinum Maestro controls all motion, interfacing with the customer’s system/user software through a dedicated .NET DLL, Elmo’s small yet powerful drives incorporate just the right algorithms to meet the customer’s requirements for adapting axis velocity on the fly, limiting the current and handling low & high acceleration, all the while maintaining high machine throughput and enabling best-in-class performance of the turret test handler machine. The customer’s success with Elmo was ensured by the following points:

- Platinum Maestro as EtherCAT master and Multi Axis controller

- Ready to use force control functions with Platinum Maestro + Platinum Solo Bell

- Wide range of drives to provide full motion solution with Elmo

- In Stock List (ISL) for quick delivery of drives for evaluation

Platinum Solo Bell

Small Servo drive

Up to 25A/100V, 9A/200V

Gold Solo Twitter

NANO Servo Drive Up to 5600 Watts

Up to 50A/60V, 70A/100V, 35A/200V

Platinum Maestro

High Precision Ethercat Muilti-Axis Motion Controller

Tambourine-20

The Tambourine (TAM-20) is Elmo’s compact, direct-to-mains power supply, designed for multiple servo drives.

Gold DC Trombone

Compact High Voltage Servo Drive

6-22A/400VDC, 8-16A/800VDC,

*900VDC optional