Elmo increases machine throughput and accuracy to speed manufacturing

The Background

The company manufactures advanced machines for bonding solid-state light-emitting diodes (LEDs) that are used in a wide variety of applications.

The Challenge

As an innovator and high-volume producer, the company was interested in faster and more cost-effective ways to produce industry-leading LEDs and wanted to improve the speed and accuracy of its automated die-bonding machines.

Elmo was challenged to produce a motion control solution that would achieve

- 90-degree PTP motion in 40 msec

- Settling time to ±25 counts in 5 msec

The Solution

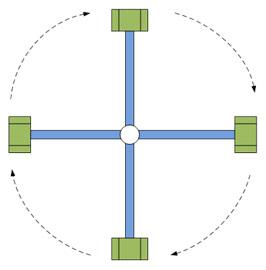

Elmo applied its solution of a direct-drive rotary motor (DDR) shaft connected to a rotational load controlled by Gold servo drives and powered by a dedicated Elmo power supply.

The Elmo solution included:

- 3-stage gain scheduling and acceleration feed-forward servo-loop functionality

- Software high-order filters for velocity and position control loops

- High-velocity position loop bandwidths

The Benefits

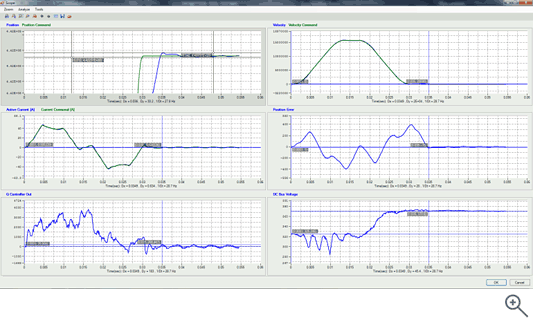

Elmo’s solution went far beyond the requirement, further reducing the motion profile to a mere 35 msecs.

With Elmo’s solution, the die-bonding machine was able to settle into a very low ±15 count position error in only 5 msecs.

Using Elmo Application Studio (EAS), several hours only were needed to successfully implement the solution.

Motion Profile results, settling into +-15 Cnt position error after 35mSec

(30mSec motion + 5mSec Settling time)

Motion Profile results, settling into +-15 Cnt position error after 35mSec (30mSec motion + 5mSec Settling time)

Elmo’s solution provided:

- Accelerated machine throughput resulting in more output in less time

- High power in a compact size to fit the limited machine space

- Fast and precise machine operation

- Advanced software functions for enhanced servo performance

- Power consumption of only 12 amps in the power supply and 18.45 amps in the motor, both well within requirements

- Fast and easy implementation process

Elmo’s solution for this die-bonding machine is the state-of-the-art in accurate and speedy motion control, saving the customer time and money in implementation and execution. With industry-leading Mean Time Between Failure (MTBF), Elmo products continue to perform reliably at the highest levels in the field.

For More Information